Fix the Problems You Know.

Uncover the Ones You Don't.

Walt Smart Radios give you control over the problems you’ve been chasing — and visibility into the ones you’ve been missing.

Most leaders already know something’s off: downtime that doesn’t add up, inconsistent output, shift confusion. Walt turns those problems into measurable signals you can act on.

And while it fixes what you’ve always seen but couldn’t solve, it also exposes the blind spots your systems overlook — safety issues never reported, teams checked out but still on the floor, knowledge lost in hallway conversations.

Walt turns frontline communication into operational clarity — and finally connects the floor to the people responsible for running it.

You Know the Problems.

Walt Helps You Solve Them.

Some challenges are obvious, like underperforming shifts, downtime with no clear cause, or updates that get lost between handoffs. The problem? You can’t measure them, predict them, or fix them with your current tools.

Walt Smart Radios change that. By bridging communication gaps, boosting visibility, and reinforcing frontline accountability, Walt gives operations leaders the data they need to take action — right when it matters.

Labor Productivity Gaps

Challenge: Certain teams underperform despite having consistent headcount and shift coverage. Leadership lacks clarity into who is productive vs just busy.

Walt Solution:

Walt Smart Radios capture real-time communication volume, responsiveness, and interaction data for each team member. Supervisors gain visibility into who is actively coordinating, who is idle, and who is disengaged, enabling more accurate assessments of labor effectiveness and overall productivity.

Limited Real-Time Operational Visibility

Challenge: Plant leadership frequently lack timely insight into frontline activities, delays, and issue resolution status across the floor. Which machines, people, or processes are causing today’s bottlenecks regardless of their physical location.

Walt Solution:

With built-in voice, photo, and video messaging, frontline workers can instantly report equipment issues, status updates, or process changes. Every message is time-stamped, archived, and assignment-tracked, giving supervisors and leadership a real-time, verifiable view of plant activity—whether they’re on-site or offsite. Walt enables live communication across voice, text, photo, and video, so leaders can immediately see which workstations are stalled, which teams need support, and where operations are breaking down—all without relying on secondhand updates or walking the floor.

Inability to Quantify the True Cost of Downtime

Challenge: Unplanned downtime is frequently underreported, misclassified, or vaguely attributed, making it difficult to analyze root causes or implement preventive actions.

Walt Solution:

Every frontline communication, whether it’s “line jam on packer 3” or “waiting on maintenance”, is automatically recorded and logged. This builds a searchable, timestamped audit trail by shift, department, and issue type, enabling teams to analyze downtime events with precision. Walt captures every call, escalation, and response, creating full traceability for each incident. Operations can now measure real delay durations, identify lag in response times, and surface recurring causes. Leadership gains the ability to distinguish avoidable disruptions from systemic issues and take informed action to reduce future downtime.

Communication Breakdowns Between Shifts and Departments

Challenge: Critical updates are often lost during shift handovers. Disputes arise between departments regarding who was notified, when, and how.

Walt Solution:

Every message sent through Walt is time-stamped, transcribed, and archived by user, group, and craft. This removes ambiguity, eliminates hearsay, and puts an end to “I told someone”excuses. Department specific channels and shift-specific channels ensure that critical updates and instructions are documented, not passed through hallway conversations or forgotten in transition. Incoming crews gain immediate visibility into unresolved issues, previous actions taken, and next steps, enabling smooth shift handovers and uninterrupted operations.

Workforce Retention and Skills Gaps

Challenge: Knowing who is about to leave or when experienced technicians depart, their institutional knowledge leaves with them. New hires face long ramp-up times due to limited hands-on guidance.

Walt Solution:

Walt serves as a real-time knowledge capture platform. Technicians can document repair steps, record voice notes, and share photos or videos directly to team or company channels. This creates a searchable, role-specific knowledge base that supports consistent execution and faster onboarding. Veteran workers can preserve critical know-how like SOP clarifications, troubleshooting methods, and best practices, so it’s accessible to new hires and cross-functional teams. The result: reduced ramp-up time, less reliance on tribal knowledge, and stronger operational consistency across shifts and experience levels.

Low Visibility Into Technology ROI

Challenge: Investments in systems like CMMS, ERP, or HRIS often underdeliver due to poor frontline adoption or limited integration with real work processes.

Walt Solution:

Walt is built for the way manufacturing teams actually work, used by every team, on every shift, without requiring a desktop or portal login. It fits naturally into daily routines on the floor, delivering immediate ROI by accelerating communication, reducing downtime, and capturing real-time data from the frontline. Unlike traditional systems, Walt doesn’t add another software layer, it becomes the connective tissue for communication, coordination, and visibility across the plant. It solves the real problem: operational misalignment caused by delays, blind spots, and fragmented information.

FREE COMPREHENSIVE GUIDE:

How Manufacturing Leaders Are Cutting $273K+ in Hidden Downtime.

Over 70% of downtime events and safety near-misses on the floor never get reported. That silence costs U.S. manufacturers hundreds of thousands every year in lost production and preventable risks.

See how leading plants uncovered $273k in hidden downtime and fixed it.

The Problems You Don’t See Coming — Until It’s Too Late

Some issues don’t show up on a dashboard. Disengaged workers. Missed safety warnings. Critical knowledge that disappears when someone walks out the door.

Walt uncovers these hidden risks in real time. By capturing and organizing frontline communication — across voice, photo, video, and text — Walt exposes the blind spots that cause costly delays, compliance issues, and operational failures before they snowball.

Invisible Worker Disengagement

Challenge: Disengaged employees often go undetected. Workers who have mentally checked out but show up everyday. No current metric or system alerts leaders until turnover or quality issues spike.

Walt Solution: Walt monitors day-to-day engagement by tracking communication frequency, responsiveness, and participation in operational threads. Are workers acknowledging dispatches, contributing to team updates, or reporting issues in real time? These signals give supervisors early visibility into disengagement, often before it affects quality, culture, or retention. With this insight, leaders can proactively coach, re-engage, or make staffing adjustments before small issues escalate into larger workforce problems.

Untraceable Safety Risks and Near-Misses

Challenge: Many safety incidents, especially near-misses and minor violations, are never formally reported. These unlogged events represent major risk for future incidents.

Walt Solution: Walt gives workers a fast, frictionless way to report hazards in real time using voice, or photos through a dedicated safety channel. Each report is time-stamped, and automatically routed to the appropriate EHS leaders or supervisors, providing immediate visibility into emerging risks across all shifts and departments. Over time, these entries build a comprehensive safety archive that captures near-misses, repeat infractions, and high-risk trends giving teams the insight they need to act before an incident becomes recordable or results in regulatory scrutiny. By removing the traditional barriers to reporting and increasing frontline participation, Walt shifts safety from a reactive compliance task to a proactive, continuous improvement process—driven by the people closest to the hazards and empowered to speak up.

Breakdown of Tribal Knowledge

Challenge: Longtime workers often possess undocumented knowledge about equipment quirks, process shortcuts, and maintenance workarounds. When they leave, that expertise leaves with them leaving the floor with a “knowledge vacuum.”

Walt Solution: Walt captures valuable frontline communication in real time, whether it’s a workaround during a repair, a key detail during a production run, or a quick fix to a recurring issue. Workers document these insights through voice, photo, or video, right in the flow of work. Each entry is automatically archived into a channel specific “knowledge base.” Over time, this becomes a living playbook that preserves institutional knowledge and ensures continuity, even as experienced employees retire or move on. Instead of walking out the door, expertise stays on the floor and is accessible to new hires, technicians, and training teams when they need it most.

Cascading Effects of Miscommunication

Challenge: A single missed or misunderstood message during a shift change or maintenance escalation can create hours of lost production, unplanned downtime, or rework without a clear root cause traced back to the message failure.

Walt Solution: Walt automatically transcribes, timestamps, and archives every piece of communication, from individual messages to group escalation messages. This gives supervisors a complete, verifiable record of who said what, when, and to whom. When issues arise, there’s no ambiguity, just a clear timeline of events. Root Cause Analysis (RCA) shifts from speculation to precision, allowing teams to isolate communication breakdowns and take corrective action with confidence.

Shadow IT and Unauthorized Processes

Challenge: Supervisors and frontline teams often implement their own systems, like text groups, or personal phones to bypass slow or disconnected internal tools. This creates data silos and compliance risks that leadership can’t see.

Walt Solution: Walt replaces fragmented, off-platform communication methods—such as personal phones, group texts, and informal messaging apps—with a centralized, purpose-built system for frontline operations. When teams rely on tools outside the company’s core infrastructure, it leads to communication silos, data gaps, and inconsistent visibility across shifts and departments. Walt eliminates these risks by providing a secure, compliant platform with access controls, automated transcription, and full auditability. By unifying all frontline communication in one system, Walt improves cross-functional coordination, protects data integrity, and gives leadership real-time visibility to drive more informed, accountable, and compliant decision-making at every level of the organization.

Misleading "Green" KPIs

Challenge: Operational dashboards may indicate that the plant is performing well—yet experienced leaders sense underlying issues. Metrics like OEE, efficiency, or attendance often fail to reflect floor-level problems like slow response times, poor shift transitions, or non-compliance.

Walt Solution: Walt provides the qualitative context that traditional quantitative metrics often overlook. While KPIs may suggest operations are running smoothly, Walt surfaces the underlying friction, such as delayed acknowledgments, slow shift transitions, unaddressed maintenance calls, and underutilized labor. By capturing these real-time signals from the floor, Walt enables leaders to reconcile “green” dashboards with actual plant performance. This deeper operational visibility supports more accurate forecasting, improved capacity planning, and continuous improvement grounded in real-world conditions, not assumptions.

A Trusted Partner in Manufacturing Communications

-1.png?width=697&height=60&name=Untitled%20design%20(10)-1.png)

What Our Customers Are Saying

See how Aspire Bakeries turned a major safety and operations challenge into a breakthrough success. In under a year, they eliminated language barriers for a 60% Spanish-speaking workforce, cut emergency response times, and boosted productivity—using the Walt Smart Radio system with real-time translation, instant alerts, and multimedia messaging. Watch how they went from communication breakdowns to 24/7 operational visibility across a 750-person, three-shift facility.

"With Walt Smart Radio, users aren't tied to a phone number—they're tied to their badge. When people leave or change departments, you don't have to manually remove them from groups. That's a game-changer for managing communication across 4,500 employees."

"If you were primarily a Spanish-speaking employee, before you had to flag someone down to get work done. Now, it’s very convenient for the team. For example, they can snap a picture, drop in a note, and send it to the maintenance team — and it catches a thread of information. Maintenance workers can say they’ve got it. Time is money for us on the floor. I don’t want someone to have to flag someone down to get something done."

"The faster you can get the facts and understand what’s going on, the faster you can make a decision to get equipment back up and running. So it really helps that after-hours troubleshooting, reducing downtime."

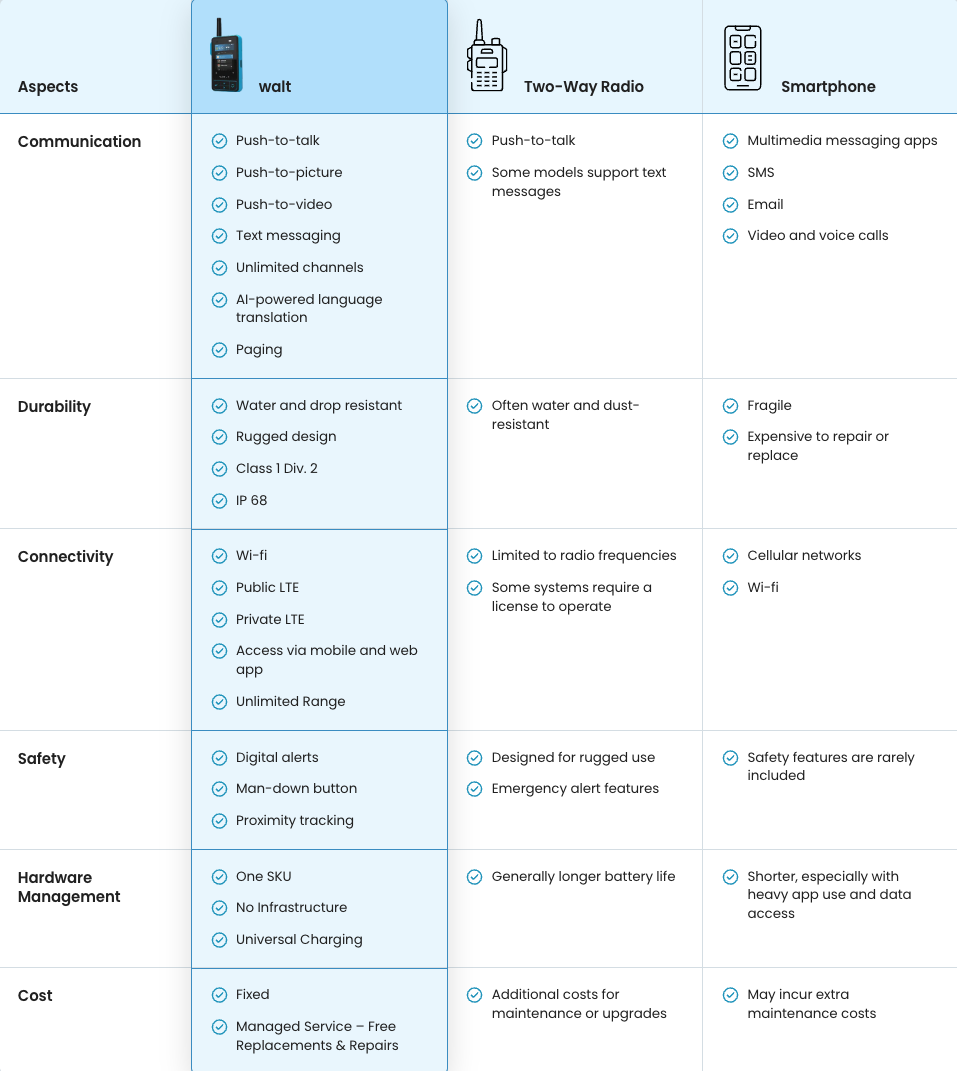

Walt vs Two-Way Radio vs Smartphone:

The Walt Smart Radio brings the best of smartphones and two-way radios, and more!

Recommended Resources

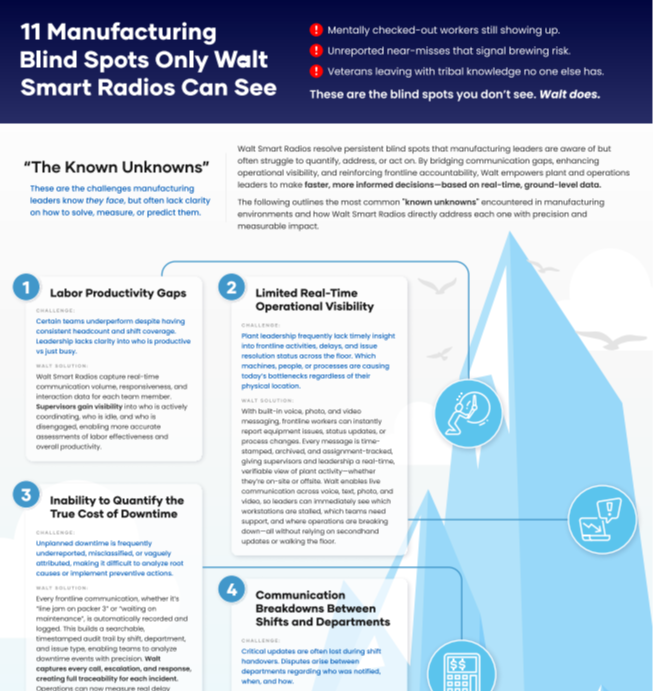

11 Manufacturing Blind Spots Only Walt Smart Radios Can See

70% of your problems are buried below the surface unknown—and traditional radios won’t show you what’s sinking productivity. This infographic breaks it all down!